The Vickers hardness tester uses the hardness test that was developed in 1924 by Smith and Sandland at Vickers Ltd as an alternative to the method that uses the Brinell hardness tester, to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests, since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness.

The basic measuring principle of the Vickers hardness tester, as with all common measures of hardness, is to observe the questioned material’s ability to resist plastic deformation from a standard source. The Vickers hardness test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH). A Vickers hardness tester must meet the following criteria:

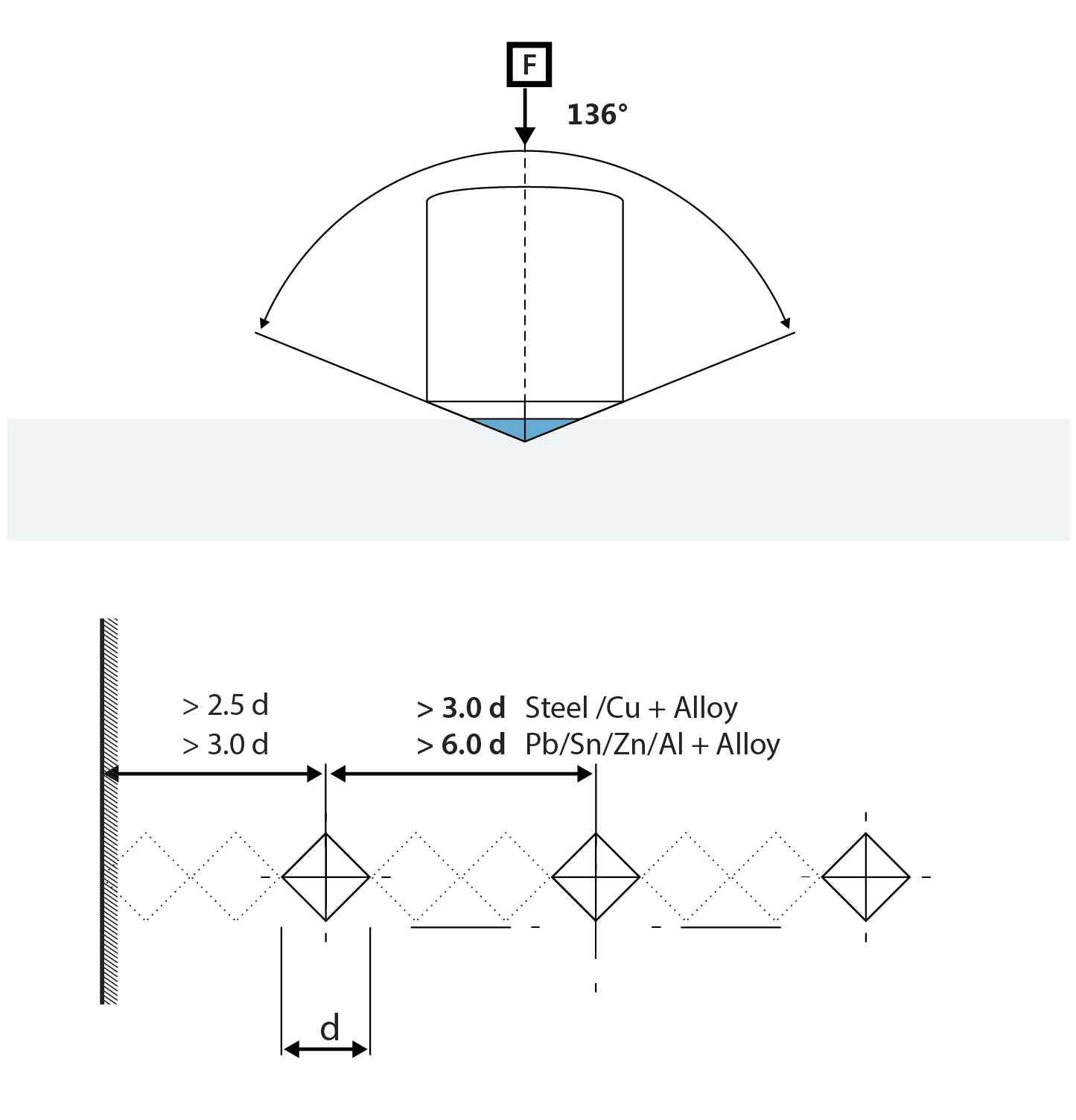

A diamond in the form of a square-based pyramid satisfied these conditions.

While performing a hardness test, Vickers hardness numbers are reported as xxxHVyy, for example: 440HV30, or xxxHVyy/zz if duration of force differs from 10s to 15s, for example 440Hv30/20, where:

Source: Wikipedia

Vickers values are generally independent of the test force, although from 500gf to 50Kgf it is possible the results of the same material under test may produce similar results irrespective of the force used. Vickers hardness tests have been found to be very useful for:

Hardness, although empirical in nature, can be correlated to tensile strength for many metals and is an indicator of wear resistance and ductility. When doing a Vickers hardness test the distance between indentations must be more than 3 indentation diameters apart to avoid interaction between the work-hardened regions. Vickers hardness testers are routinely used for testing materials, components in the aerospace and automotive industry, laboratories for sample evaluation and to conduct common or advanced testing tasks.

Do you have any questions or would you like to receive more information about the Vickers hardness tester or other hardness testers, such as the Rockwell hardness tester or Knoop hardness tester? Please contact our specialists, they would be happy to help you.